PM – What inspired you to start JWJ Guitars?

Richard Jones – I’d always had a dream that one day I would make a living working with guitars, although it seemed unlikely to happen. Then, about four years ago various unplanned events happened in my work and home life which led me to the decision to make some big changes and start something new.

PM – Did you have any experience of making musical instruments before starting out?

RJ – I built my first guitar about 20 years ago after years of repairing and generally tinkering with them. That was a Les Paul copy, and then I did a few more electrics before trying an acoustic. After that I mostly stuck with acoustics as I just find the whole process more satisfying.

PM – Can you tell us a bit about what makes the JWJ series special?

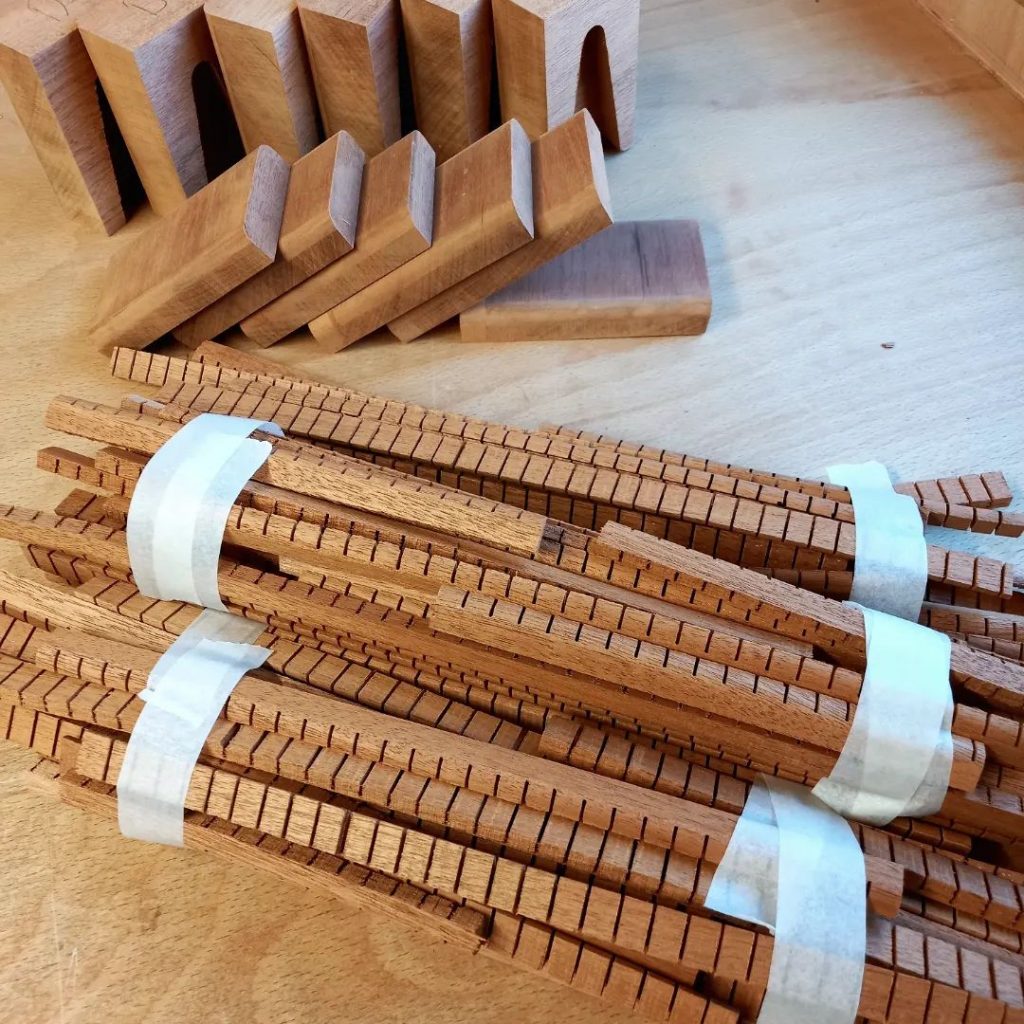

RJ – Hopefully it’s the feel and tone of the instruments, that’s what I’m focused on. Neck profiles have become a bit of an obsession of mine and I’m still trying new things, but I’m really proud of the four profiles I currently offer, especially the Asymmetric profile which is kind of an amalgamation of the other three. Tone-wise I aim for really lively and resonant guitars that you feel moving against your body whilst you play. Getting a good bass response really helps with that, as does selecting pieces of wood that I think complement each other.

PM – What is the best thing about being a luthier?

RJ – Like most people I’ve always had a list of projects in my head that I’d like to get around to if I had the time. For me quite a few of those were guitar builds so now I’m slowly getting through them! I do feel really lucky to spend my time doing the thing I love and be able to earn a living doing it.

PM – How do you select which tonewoods you use?

RJ – Most of my stock comes from Timberline in the UK who provide fantastic quality tonewoods and have years of experience doing so. I also scour the internet for unusual or interesting pieces. From there I try to match things up by a combination of listening, looking and feeling each piece. So for example if I have a top that’s got quite a wide grain, feels really flexible and has a quite an open tap tone, I’m going to try and find some bracing wood that’s a bit tighter sounding and stiffer to balance it up on a bigger guitar, but maybe on a smaller guitar I might look for something similar to let the top vibrate more.

PM – The JWJ models have a very distinct volute, why is this important?

RJ – It’s just there to add a bit of strength to the weakest point of the neck and hopefully avoid breakages. I want my guitars to last a lifetime.

PM – What is the hardest part about making a guitar?

RJ – Lacquering is usually the most challenging part and it’s been a steep learning curve, but a lot of people comment on the finish which makes it worthwhile.

PM – Do you ever miss any of the guitars that you have made/sold?

RJ – I’m already missing the Redwood/Koa Orchestra you have in store!

PM – What is the one thing in your workshop you couldn’t do without?

RJ – My vacuum cleaner – I hate mess!

PM – Where did the name JWJ come from?

RJ – I’d built under my own name before but this was a new start for me and I knew the quality of the guitars was going to be a step up from what I’d done before so I needed a new name. My Dad’s initials are JWJ and so are my son’s so that’s always meant something to me. I’ve always liked symmetry (except sometimes on neck profiles…) so I had the idea to flip the second J around for the logo, which a friend helped to create.

PM – If you could describe JWJ in one sentence what would it be?

RJ – I’m just trying to create guitars that would excite me as a customer and player.